Reate use secondary hardening for their heat treatment protocol. This method uses 3 high temperature tempers around 500°c and in simplistic terms, creates harder carbides.

This method at minimum requires 3 tempers and due to this is often thought to not work because that is often over looked. A con to this method is the reduction of chromium in solution, due to converting it to the harder carbides. If a steel with a high enough chromium content is used and a low enough austenitizing temperature, enough chromium can still be good enough for stainlessness, but no where near what it could be in the lower tempering temps. So surface finishes like bead blasting should be avoided.

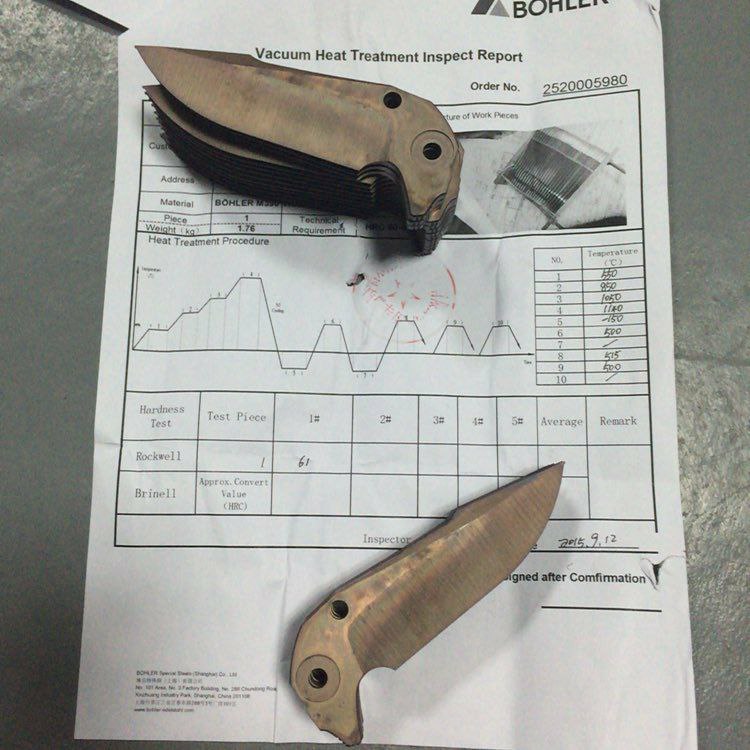

Reates protocol is as follows…

- 550c

- 850c

- 1050c

- 1140c

- -150c

- 500c

- 515c

- 500c

The knives are sent to Bohler China which does not make any steel but offer’s services including heat treatment. It’s anyone’s guess as to why Reate chose to go with secondary hardening and Bohler to do the Heat treatment, but it is said that Todd Begg and his brother may have had a say in it. But nothing conclusive on that.

The protocol can be seen here: https://www.Instagram.com/p/7kYbhVzDSz/ Mirror: https://t.me/carbide_microstructure/85

The Source of the protocol is from Solo Designer on Instagram. This is David Dang’s (the Owner of Reate) brother. His American name is Jack and he designs many of the in house designs including the JACK series.

The target hardness is 61 and they sometimes range less than this. But because of the harder carbides in solution they will often still perform better than anyone not using secondary hardening.

There are many examples of some duds that just dont cut well at all. With any mass production knife companies, there will always be a few duds. I personally have one and outpost76 has also tested a dud. Also some have been hardness tested lower than 60rc.

The Testing:

60hrc Reate Horizon D m390 15° https://youtu.be/ZcjVhrmwA9g

Mirror: https://t.me/carbide_microstructure/84

Chaves 229 in m390 manufactured by Reate hrc tested at 61hrc.

Chaves 229 M390 vs Protech FF Mordax 20CV edge retention testing, one surprise along with a let down

Chaves 229 M390 done by Reate Knives vs the Ferrum Forge design Mordax 20CV done by Protech. Welcome a new member to the land if sadness and disappointment. Which one will it be? Thanks to Kenny at Inthepocket for sending these 2 to test and check out.

https://www.youtube.com/watch?v=T90fQyc9BpI

Mirror: https://t.me/carbide_microstructure/200

Reate K1 M390 edge retention testing, what does Reate have to offer in this example