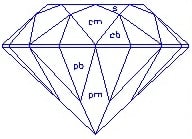

I have this commission to cut a pair of 4mm pyrope garnets. Pyrope garnets are almost ruby red in color and can come very color saturated, meaning very very dark. These kinds of stones have to be cut a particular way or they will end up being too dark and not provide enough light return.

I found two stones in my inventory that met the needs of the commission, and both seemed like they would work well with little to no issues inside the stone that I could see with my loupe and a light source. So I started to rough the first stone out.

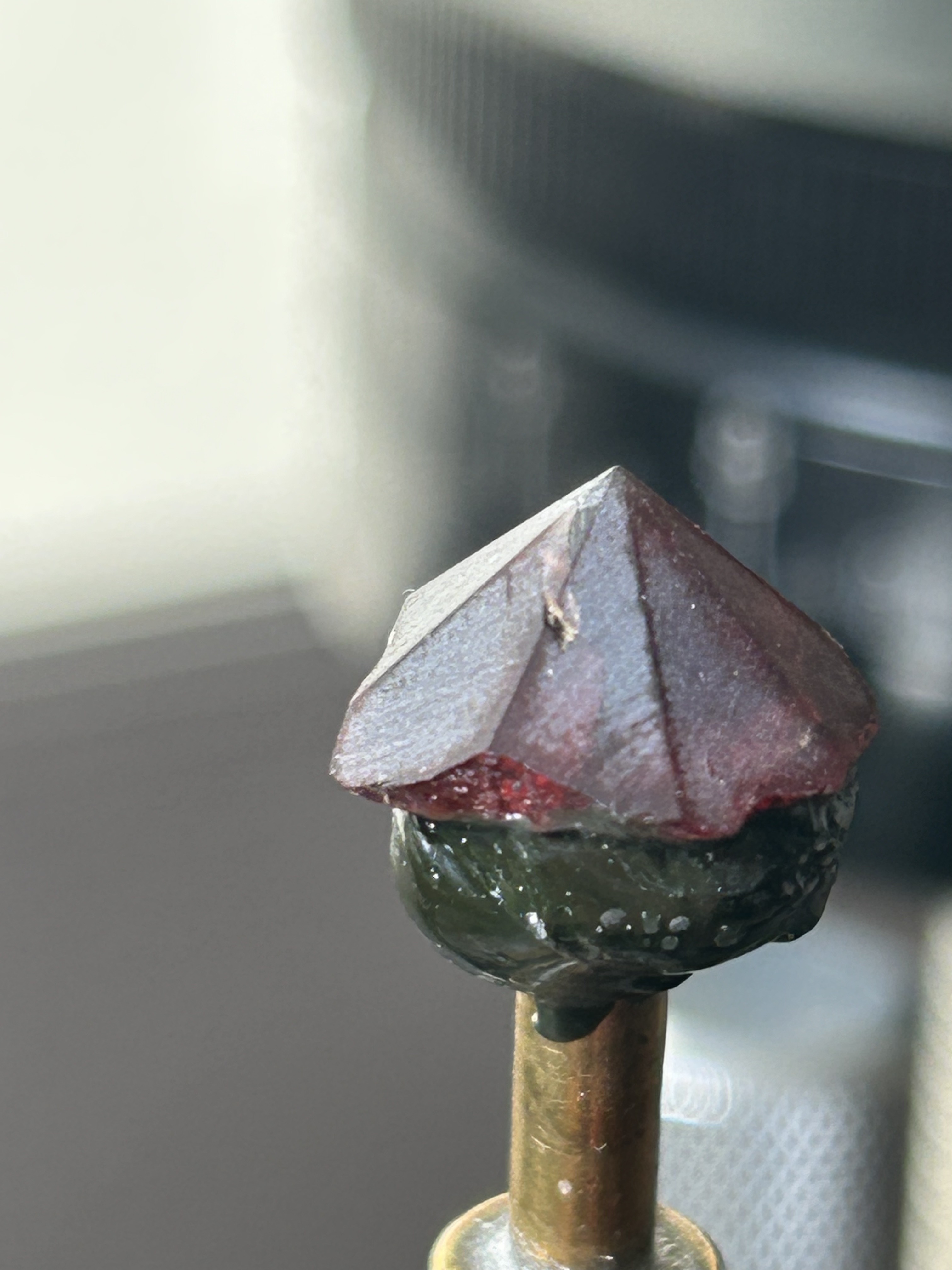

Well this isn’t totally unexpected, as it being a super color saturated stone, I might have missed an inclusion. So the solution to this is to try and keep cutting through it to get past it.

Ok, now that doesn’t bode well. Nothing to do but see how bad this is and keep cutting.

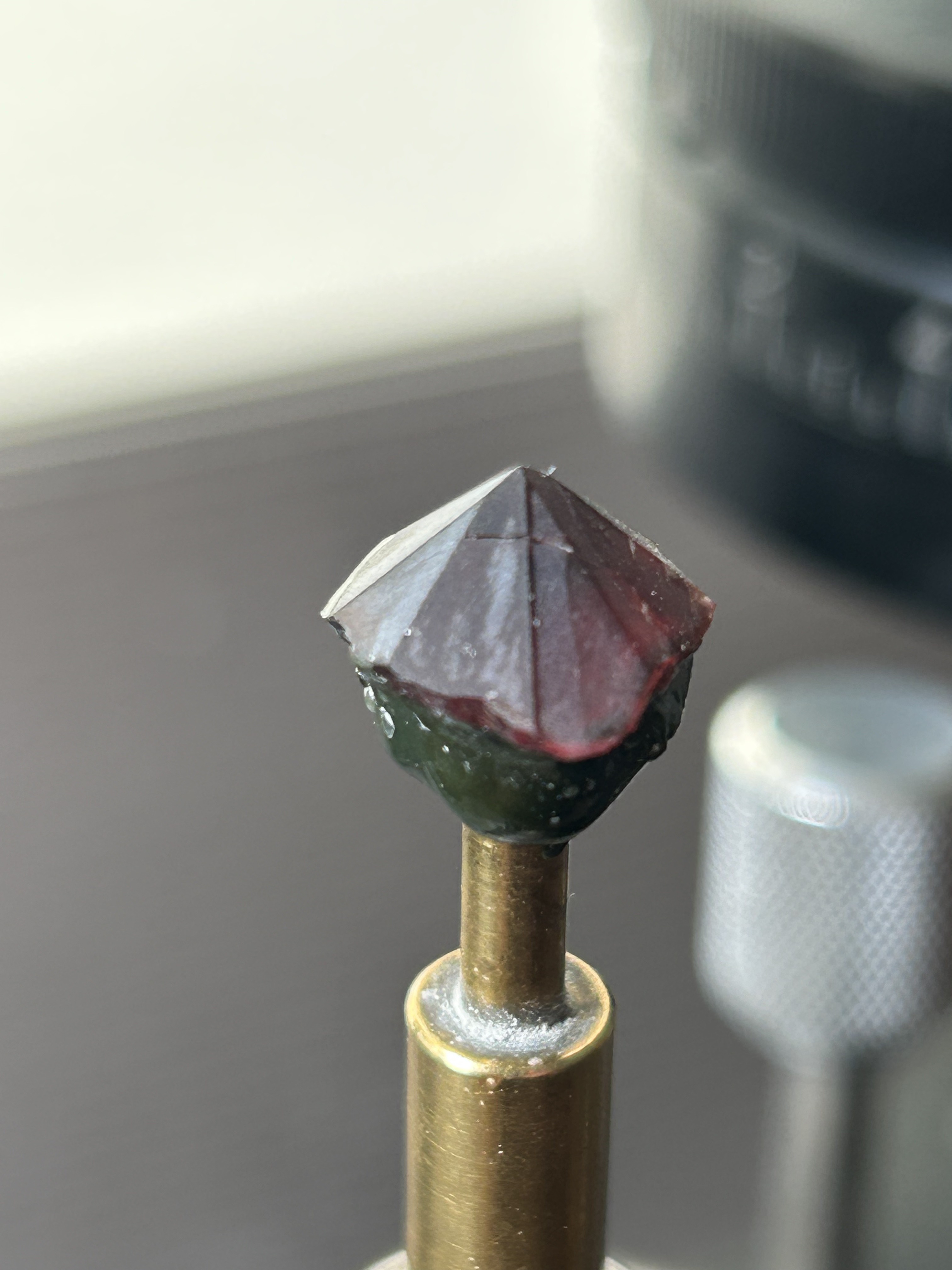

Ok, this stone is a total loss at the target size. The fracture runs through almost the center of the stone.

You can see clearly the section that is separated by the fracture when the stone is lit up. That section has to come off and doing so will make the stone too small for the commission. I’ll have to go find another stone of similar color and size.

Sometimes lady luck is taking a vacation.

Coming from all, I never realized how interesting this process is. Please update when it’s finished!

If you haven’t done so, look at my past posts. I did a series of posts describing the process I use to cut stones from start to finish.

This is a fascinating subject, thank you for sharing all of your posts. I love finding new topics like this that allow me to briefly dive into something, discovering processes( and even new vocabulary) that I never pondered before.

I work in a *very *unrelated field, but often times marvel at just how impossible it seems that any of it was accomplished before the invention of the modern tools I use daily.

Do you ever look at renaissance era lapidaries and feel that way as well? I understand this level of faceting is a modern invention, but with no precision tooling at all, it seems amazing that any of the old jewels were ever created in the first place.

One of the first types of machines invented is the jam peg. This machine is actually still in use, albeit a bit more precise. This machine had a mast with a series of angled holes that the cutter would stick their dop in. Each hole was at a different depth/height and different angle.

Much of what was done in the past still is in use now, which is amazing. The biggest refinement to this craft is the precision and cad software that makes it easy to be very creative with stone designs. Additionally the the synthetic stones have become more prevalent and of a higher quality. Synthetics are the same material as natural, it’s not mined and are often better quality.

If you really want to go down the rabbit hole, check out Justin K Prim’s channel he has done many videos around techniques, history etc.

Any memmy users here who know how to view all the images in a post?